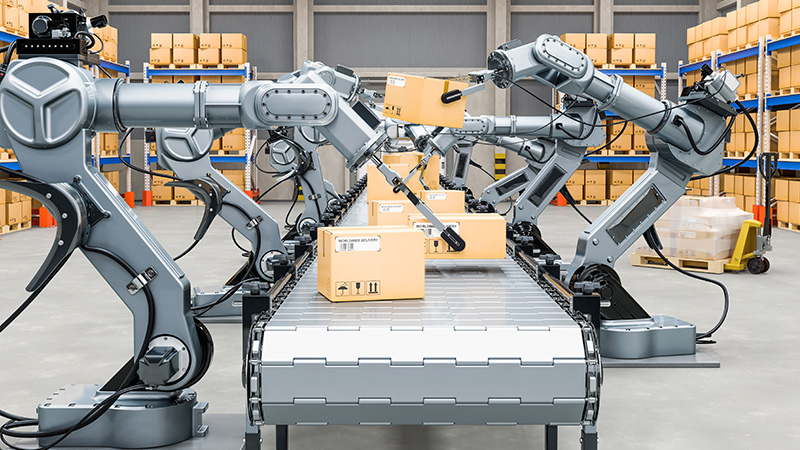

At a time when more and more consumers expect to receive their packages the next – if not the same – day, leading online and retail firms are turning to robots for holiday help this season. Amazon says it expects costs to double in Q4 from Q2 to meet demand for its Prime one-day shipping, including hiring tens of thousands of workers for the busy holidays.

This surge in speed for packages – and increase in sheer volume – will have countless warehouse workers getting a hand from robots for the first time. France-based Geodis SA, a $9 billion global supply chain company, will boost its robotic workforce by 75 percent to help workers at its U.S. warehouses fulfill orders during the holiday peak. This year, the company plans to bring on as many as 7,000 new people for the holidays and are placing 281 Locus robots in five of their warehouses.

Randy Tucker, President and CEO of Geodis Americas, says that well-timed benefits of augmenting labor with robots are many. “All of our robots run on power and need to get their batteries charged but they rarely call in sick. A few years ago, we were worried if our teammates would be concerned with robots in their workspaces. But we had unintended consequences. We underestimated the ‘cool factor’. Teammates clamored to get in the warehouses with robots and even named them all.”

Tucker further says workers realized robots made life easier for them by doing some of the most manual and repetitive tasks, while removing language barriers. For French speakers, Geodis’ robots can be programmed to speak in the company’s home language. (They can also ‘speak’ Spanish, Japanese, Burmese and Chinese.) He adds their robots aren’t displacing any workers at present but augmenting human labor. Even with the U.S. unemployment at historic lows of 3.7 percent, in industrial markets, it can drop as low as 2.2 percent. This, combined with the need to move product at unprecedented speed, is “forcing any company in the retail and transport industries to re-think warehousing and distribution,” Tucker notes.

inVia Robotics, based in Los Angeles, provides companies with robots on a monthly subscription model or Robotics-as-a-Service. Co-founder and CEO Lior Elazary says their model is especially enticing for small and medium-sized companies that compete with the Amazons of the world.

"We are able to get our robotic system up and running quickly because it adapts to an existing warehouse. Customers can have new, more efficient workflows in place in a matter of days," says Elazary.

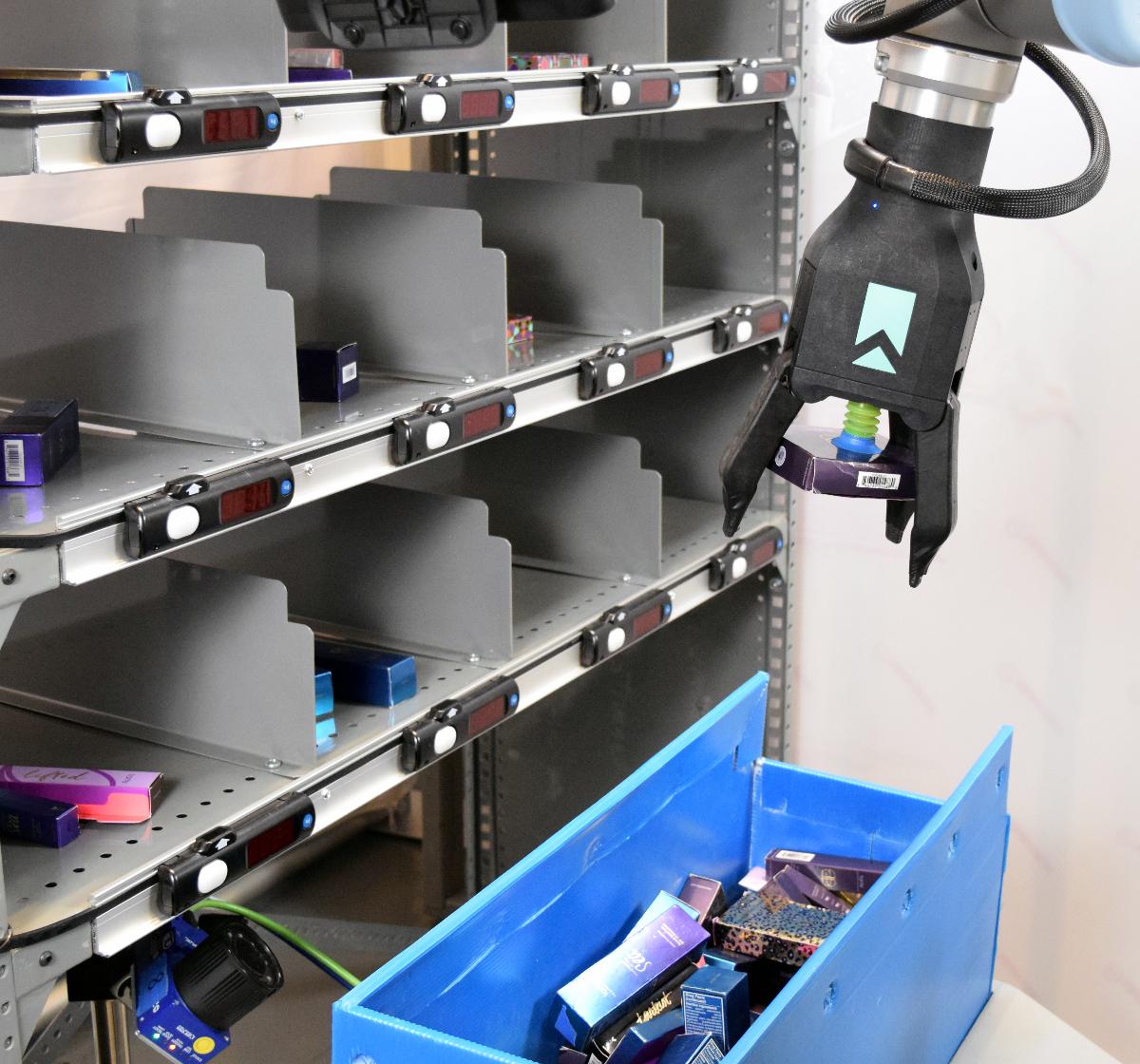

Many warehouse workers pick-and-fill items from bins or shelves – repetitive and physically strenuous work that can be backbreaking and dull. RightHand Robotics, right outside of Boston, lends a helping hand though an AI-embedded one. Their pick-and-place system, called RightPick2, has robots with mechanical grippers with human-like dexterity.

“In industries such as e-commerce, grocery and pharmaceuticals, our piece-picking solution can pick accurately hour after hour, freeing up humans to do higher skill tasks that are more fulfilling,” explains Vince Martinelli, head of Product and Marketing who worked at Kiva Systems, now Amazon Robotics, before RightHand, “The system includes a proprietary hybrid gripper with compliant fingers and suction cup along with a vision system that leverages machine learning algorithms and data to handle a wide range of items, reliably and at a high rate."

The 2019 MHI or Machine-Human Interface report from Deloitte surveyed 1,000 respondents from a wide range of manufacturing and supply chain industries. It found hiring qualified workers as the single biggest challenge for supply chain leaders.

The report also found that the highest near-term funding will be for Robotics and Automation, an area where in which companies plan to spend $20 million on average over the next two years.

Mehdi Miremadi leads Intelligent Manufacturing for McKinsey & Company in Chicago. He says automation is leading to a whole new era of business transformation for industrial companies.

“New robots learn about their own failure modes and take corrective decisions to become more efficient, and so you have a much shorter feedback loop to improve quality of the products they produce. New robotic arms, for instance, are totally data driven. You can turn all the data they receive through their sensors into numbers and algorithms they can share with other machines. All of a sudden, this opens the doors to adjusting things faster and collaborating at larger scale,” adds Miremadi.

Although robots are most prevalent in the crucial pick-and-fill process in today’s warehouses, they’re starting to play a bigger role in inventory control, as well as in inbound and outbound handling. A once relatively straightforward world of storage and fulfillment has become a world of increasing complexity, change and challenge. The pressure on supply chains to perform more efficiently has never been greater – just ask Santa’s elves – as customer expectations for smoother and faster delivery will only increase.

###

The contents or opinions in this feature are independent and may not necessarily represent the views of Cisco. They are offered in an effort to encourage continuing conversations on a broad range of innovative technology subjects. We welcome your comments and engagement.

We welcome the re-use, republication, and distribution of "The Network" content. Please credit us with the following information: Used with the permission of http://thenetwork.cisco.com/.