In the animated film Wall-E, humans abandon Earth when it’s overrun with trash.

It is a future that Cisco engineers hope to avoid.

“Unless you want to live on Wall-E's trash planet,” said Tom Jackson, Cisco’s senior director of product operations, “you have to start changing the way you approach your design.”

To that end, Cisco has reached a critical goal it set several years ago. As of the end of fiscal year 2025, 100% of Cisco’s new products and packaging now incorporate Circular Design Principles.

Behind the achievement is a comprehensive effort to minimize waste, create modular components, use recycled and renewable materials, extend product life, and reduce energy usage, wherever possible. At the same time, embedding circular design earlier in the product development process helps to enable reuse, repair, and recycling.

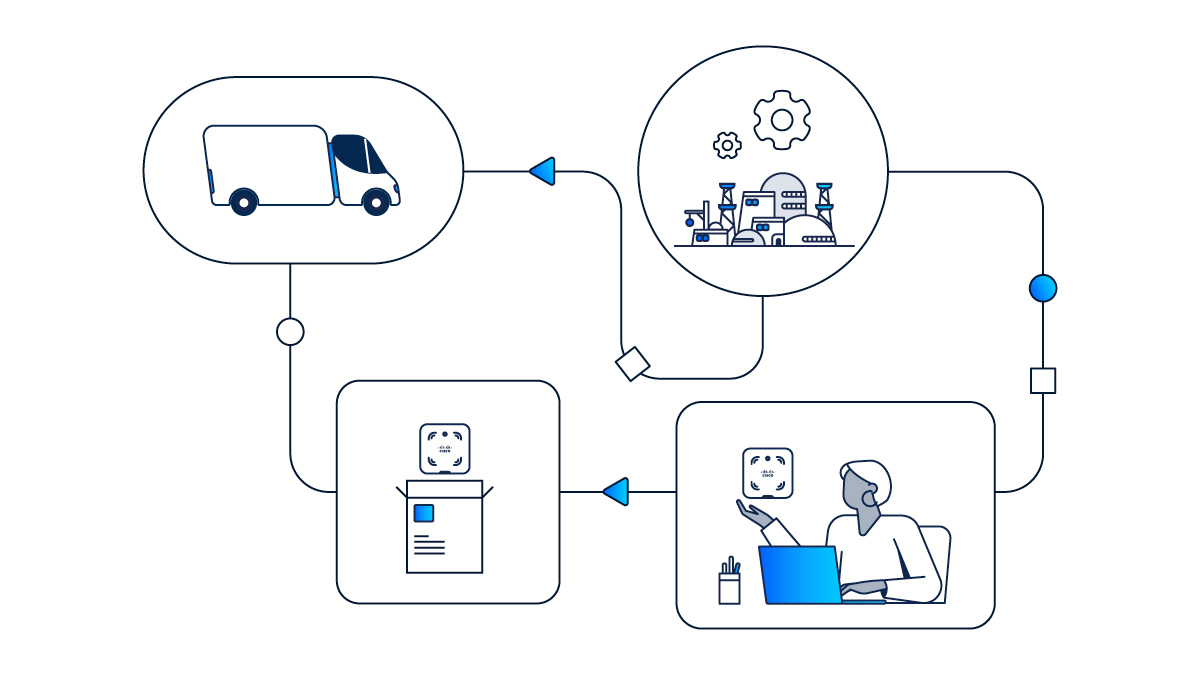

Circular design is a critical part of Cisco’s efforts to transition to a circular business model, which finds new uses for products and the materials they are made from. But reaching the 100% milestone demanded top-down commitment and sweeping organizational change.

“Once we had buy-in and support from the leadership team there was no going back to the old ways,” said Jackson. “We needed an entire culture shift around the way we design our products and work with our vendors. Thousands of people had to retrain and take action.”

In other words, it came down to hard work.

“It’s easy to set goals,” said David Stallings, Cisco’s VP for switching hardware development. “It’s much harder to embed it in your engineering processes at the bottom and work your way up, and that’s what we’ve done. It’s pretty rare in our industry at this point.”

Mary de Wysocki, Cisco’s chief sustainability officer, applauded the achievement, for its alignment with Cisco’s purpose, its innovative spirit, and the concerted effort that made it happen.

“As we embed our Purpose into our products,” she stressed, “our engineers are thinking about not just creating, say, a server with the greatest bandwidth and security or the best collaborative experience. They’re thinking about designing in those circular design principles, creating efficiencies, reducing waste, and building for multiple life cycles.”

For the planet, and for the business

While circular design can benefit the planet, it can also make great business sense, by helping to lower costs for packaging, raw materials, energy usage, and more. For example, Kelsi Doran, Cisco’s vice president for sustainability and purpose strategy, mentioned the impact from eliminating oil-based paint from the company’s Catalyst 9000 series products. From that one decision, Cisco estimates savings of up to $9 million from FY 2020 to 2025, while eliminating 3,400 metric tons of CO2 from the manufacturing process. At the same time, the products are easier to recycle.

Speaking of recycling, e-waste represents a vast untapped source of precious metals and other raw materials. The Global E-Waste Monitor estimated that up to $62 billion in gold, titanium, nickel, silver, copper and more were unrecovered in 2022. So, reclaiming such materials is critical. That’s why Cisco is investing in innovations to make the process more cost effective and environmentally sound.

Circular design also helps to drive less tangible benefits, for example around brand reputation and talent acquisition.

On all fronts, customers and industry leaders are taking note.

“When I talk about this program with industry peers and other companies that are driving circularity, it’s met with great interest,” Doran said. “It’s seen as something that is unique, pioneering, and industry leading.”

In particular, she sees excitement around how circularity is embedded from the earliest design stages — as well as the cost savings that can result.

“When you design to minimize waste,” Doran added, “you're designing cost-savings in.”

Stallings agreed.

“In terms of ROI,” he explained, “it’s about making products that live longer, making products that are fanless, that are paintless, that can potentially last longer.”

Once they do reach end of life, circularity’s next phase kicks in.

“We'll take back anything with a Cisco logo, at any time at our cost,” Stallings continued, “and we'll either find a second home for it through Cisco Refresh or we’ll send it to recycling and get the raw materials back into the forward value stream. Those all make money for the bottom line.”

The company's commitment to circular design doesn't stop at products.

Foam packaging is but one example.

“In fiscal year 2019, we set the goal that we would reduce our use of foam [by weight] by 75% by 2025,” said Jackson. “That spongey foam is really good at doing its job. It's cushiony, it's very lightweight, and it's cheap. But it’s not great for the environment, and there's almost no end-of-life use for it.”

The solution — after much experimentation — was to create a new solution from recycled plastic detergent bottles that cushions products in shipping. But the team is exploring an even better solution: using biodegradable fiber-flute materials, made from cardboard, to cushion products during shipping.

Next up: Circular Design 2.0

That speaks to a key element of Cisco’s sustainability goals: no one is resting on their laurels.

The company is setting new goals for Circular Design 2.0, its next, more advanced phase. This will aim to further increase Cisco’s standards through more responsible manufacturing practices, improved data access, smarter energy monitoring, and continued efforts to reduce environmental impact.

Jackson explained one aspect of a much wider, ongoing effort.

“We’re looking to Circular Design 2.0 and beyond,” he said. “And one of the journeys we’re on is to get a better ingredients list for components. David’s team might put a thousand different components on a PC board. But what are they made of? What are their core materials, and what percentage is recycled material? We don’t always know. It’s a problem of data that we're working to solve.”

Of course, energy usage is a major concern, especially as adoption of energy-intensive technologies like AI continues to accelerate.

“Our job is to do everything we can in our systems to make them as efficient as possible so that they're using the least amount of max power and the least amount of real-time power,” Stallings explained. “So, we have intelligent algorithms in our systems that are monitoring the data and are throttling interfaces to the lowest possible power levels. That's something we never would have even considered five years ago.”

Doran sees culture as a key element in setting — and reaching — sustainability goals.

“One of the things I see in my role,” Doran stressed, “is just how much our employees care about sustainability. Our culture at Cisco is one where we have attracted a lot of people that care about these topics.”

To that end, Stallings emphasized that no matter how innovative or competitive Cisco’s circular solutions become, the subject of patents never arises.

“We would never keep it to ourselves,” he said. “We are more than happy to share our journey with anybody, and we're more than willing to partner with anybody.”

“It gets back to the core,” Jackson concluded. “If we’re experts in circularity and others are still generating all this waste, then we’re not following our purpose. Because we’re all in the same boat, and nobody wants to end up on Wall-E’s trash planet.”